The evaporation phenomenon is still being discovered and studied. There are many factors when examining natural evaporation, such as water temperature, wind, humidity, water vapor pressure, dew point, outside temperature, and many more. There are also many factors to consider when choosing to introduce enhanced evaporation into your process. This post will clarify some main differences between EK’s mechanical rotary atomization versus pressurized spiral and pressurized hollow nozzles.

EK’s rotary atomizer consists of a small compact 6-hp electric motor that can operate at speeds between 2000 and 15000 rpm’s using a variable frequency driver (VFD). The rotary atomizer hub (Figure 1) is 3D printed and made with polypropylene giving it maximum durability in the harshest water conditions. Since the atomizer hub is 3D printed, it allows for customization patterns for high TDS wastewaters. The 1” water inlet initially fractures and distributes the water evenly before dropping inside the atomizer hub. This process keeps all water away from the motor shaft and the motor shaft seal. The water flow needed is similar to a garden hose faucet and engineered for a maximum flow rate of 20 GPM.

Figure 1. EK Atomizer Hub/Water Inlet

The water inflow is fractured through the EK’s atomizer hub using centrifugal force and allows higher TDS waters to flow smoothly through the atomizing hub without causing significant friction or wear. The slow-motion video shows the fracturing of produced water into tiny droplets.

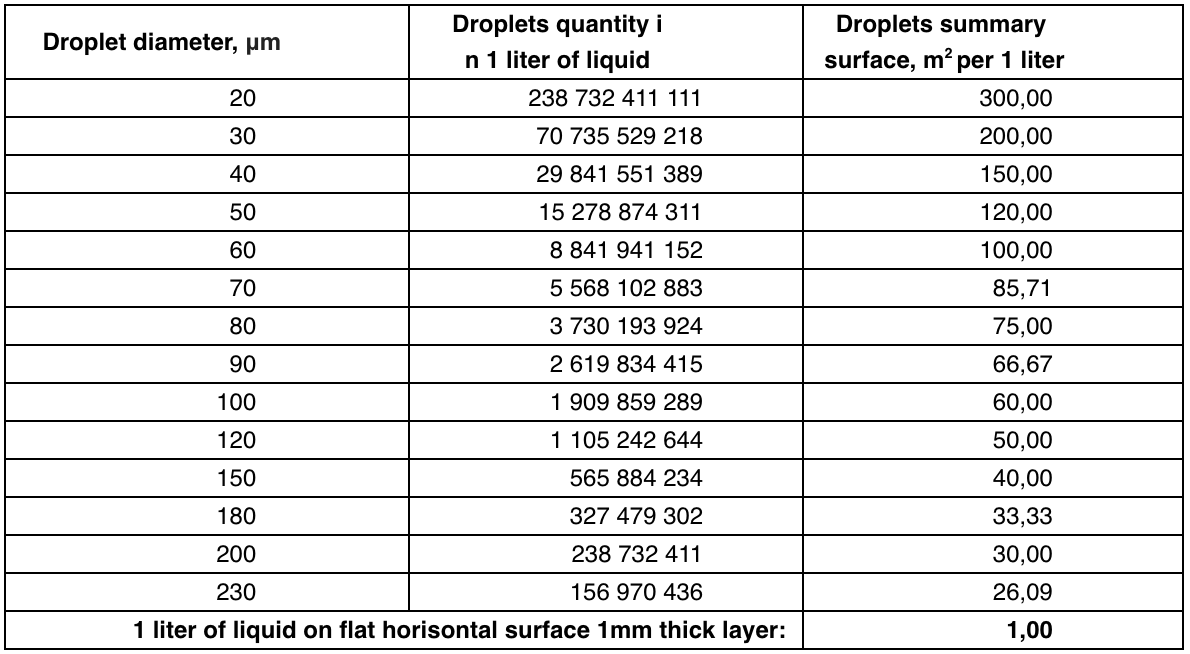

Once the atomizer reaches higher speeds, the smaller the droplets become, creating more surface area of the throughput volume (Table 1).

Table 1: Surface area of tiny micron drops

Table 1: Surface area of tiny micron drops

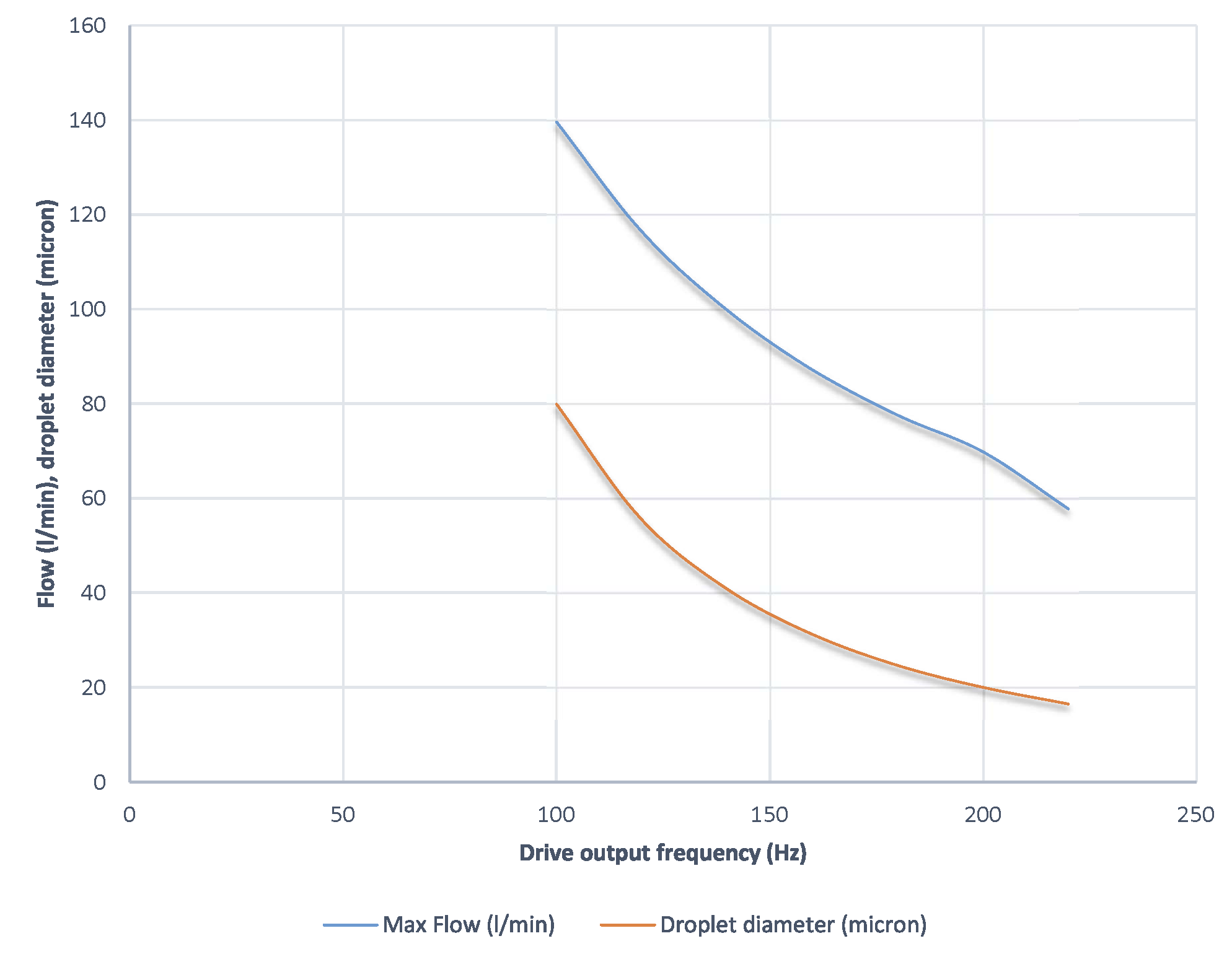

EK’s droplet spectra have the highest industry average between 20-50 microns (Figure 2). Creating this much surface area allows for a faster evaporation rate and lowers the typical pond size requirements by a 10 to 1 ratio. Rotary atomization enables the manipulation of droplet sizes by changing the speed of the atomizer that allows control during any overspray conditions. Spiral and pressure nozzles only operate in an on and off operation to control overspray. The only way to change droplet sizes is through nozzle replacement or water pressure changes.

Figure 2: EK’s Micron Spectra

Figure 2: EK’s Micron Spectra

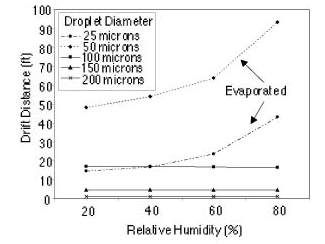

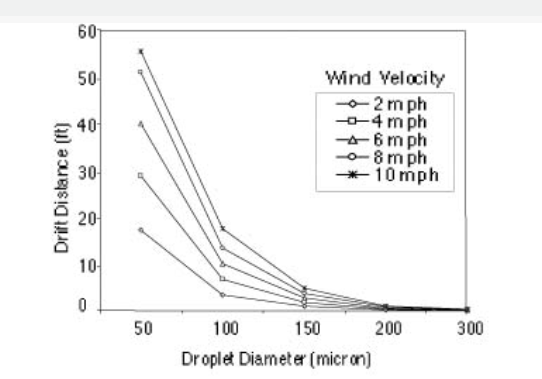

Why is it essential to know droplet spectrums for enhanced evaporation equipment? There are two main reasons, one is related to performance, and the other is related to overspray conditions. An Ohio State drift study concluded that water droplets <50 microns evaporate entirely within 18 inches from the discharge point in relative humidity levels between 20-80% (Figure 3). The same study also analyzes the drift distances of different size droplets using changing weather and wind speed inputs (Figure 4).

Figure 3: 25-50 micron droplets evaporate the quickest

Figure 3: 25-50 micron droplets evaporate the quickest

Figure 4. Drift distances for 50-micron drop

Figure 4. Drift distances for 50-micron drop

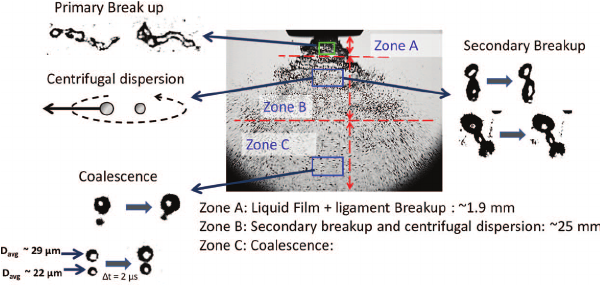

The Spraying Systems Co. 8-15W nozzle used on Minetek’s snowmaking type cannon operates at 40 psi. The 8-15W nozzle has a mean water droplet average of 500 to 600 microns (Figure 5). Mintek uses over 270 8-15W pressure nozzles to obtain a 25 L/S flow rate. These nozzles are spaced very tightly around the end of the cannon creating multiple collisions of 500-micron droplets due to each nozzle having a 100° cone spray angle. See WhirlJet nozzle cone spray video. Several studies regarding the collision coalescence of water droplets prove droplets increase in size as they move away from the nozzle. “During this process, smaller droplets collide, form larger droplets, and lose their momentum due to drag. Thus, the droplet diameter starts increasing away from the nozzle. As the droplets become larger and slower, the probability of subsequent droplet-droplet collision increases, resulting in further coalescence.” https://aip.scitation.org/doi/10.1063/1.4773065

Figure 6. Hollow Pressure Nozzle Coalescence Zone

A recent white paper released by Minetek explains the use of the 500-micron nozzle from Spraying Systems Co. The main reason for the nozzle's choice is that it provides higher flow rates and is less likely to clog. “Large-bore nozzles were selected to maximize throughput and prevent blockages by entrained solids.” The paper continues by stating that a single unit can pump 600 GPM and blow it up to 150’ high into the air. The most intriguing point made in this paper is the 50% evaporation rate based solely on the droplet size reduction and not droplet reduction. The reference section of the report mentions the droplet size information used was from a dust suppression upgrade project using the same Spraying Systems Co. nozzle. However, the reference cited seems to suggest the complete opposite of using the nozzle size and flow rates for evaporation. Here are the critical highlights from the Project showing that the best use of the same nozzles is best for dust suppression:

-

Although beneficial in regards to overspray, Evaporation is not a significant factor for the VMD droplet sizes produced by the proposed nozzles.

-

For the prevention of dust generation for stockpiles, standard hydraulic nozzles that produce drops between 200 and 1200 μm are generally used.

-

The size of the droplet affects the vertical velocity at which it falls. A larger droplet will fall at a greater speed than a smaller droplet in the same conditions.

-

500-micron droplets fall in a speed similar to a light rain.

-

Water drops that are greater than 300 μm in diameter will experience negligible evaporation from a fall over 1000 m in an atmosphere with a relative humidity as low as 40% (Pruppacher & Klett, 1980; Gunn & Kinzer, 1951).

-

Since the fall distance from the Spray Tower will be no more than 40 m and the VMD is 500 μm, we are basically off the chart, i.e., the effects of evaporation for the VMD can be disregarded.

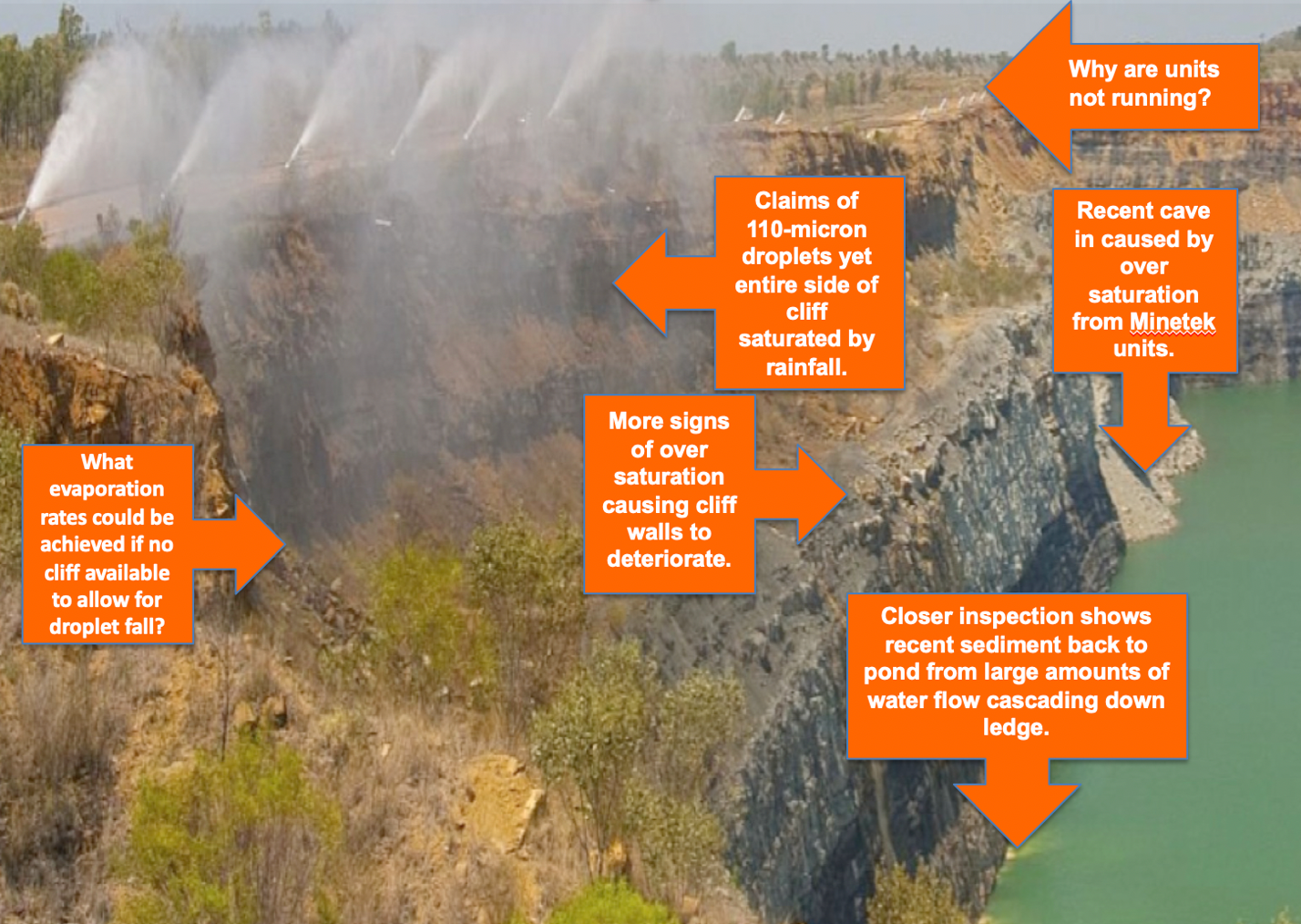

Figure 7 shows the light rainfall effects of shooting 500-micron water over a sizeable open-pit mine wall, and the results speak for themselves. The question to consider in using snow cannon pressurized nozzle technology is, do you have over 1000 m of drop on your project site for a 500-micron drop to evaporate completely.

Figure 7. Minetek units operating over open pit mine site

Figure 7. Minetek units operating over open pit mine site

Other snowmaking/evaporation cannon-style systems use pressurized spiral nozzles to obtain droplet fracturing. See Figure 8.

Figure 8. TF Series Spiral Nozzle by Bete

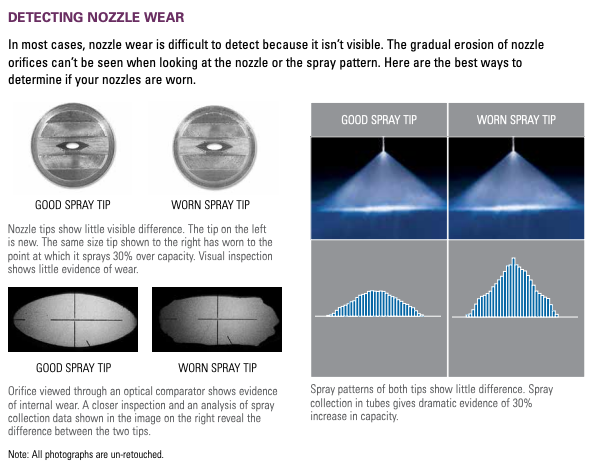

Bete and Spray Systems manufactures a typical spiral nozzle for disposal purposes. Helical nozzles need pressures between 40 to 400 psi to gain required flow rates. The snow cannon system places approximately 30 of these nozzles on a 2” ring and is placed tightly together and angled towards the inner core of the cannon face. Flow rates vary based on the pressure provided by secondary pump systems. The increased pressure from the pump system increases flow rates through the spiral nozzle and improves atomization. Because forces are higher with helical nozzles, wear is a considerable challenge to detect. As these nozzles deteriorate and wear, increased flow rates or lower spraying pressures increase droplet size. Figure 9 shows how difficult it is to monitor wear in a spiral nozzle. In applications with higher TDS, nozzle tip wear would be challenging to detect and, in essence, create challenges in evaporation droplet sizes, not to mention the increased merging of drops.

Figure 9. Tip Wear in Spray Systems Technical Appendix

Figure 9. Tip Wear in Spray Systems Technical Appendix

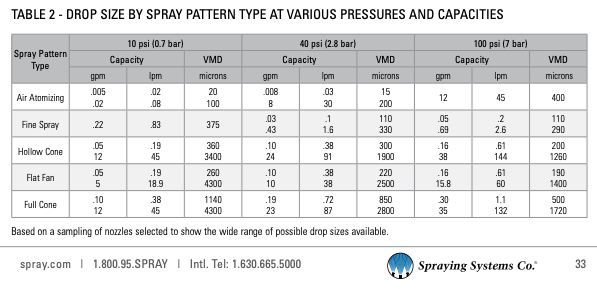

Spray Systems Technical Reference Appendix shows average droplet sizes produced from spiral nozzles, shown in Spray Systems Technical Reference Appendix, with a snapshot shown in Figure 10. Based on typical pressures and flow rates, the average micron calculation for a hollow cone spiral nozzle is between 200 microns at a flow rate of 0.16 GPM up to 1250 microns at 38 GPM. The approximate flow rate for a 30 nozzle system would be approximately 3.6 GPM, which would likely place the droplet sizing between 300-400 microns, making this nozzle friendlier for dust suppression.

Figure 10. Hollow Cone Spiral Nozzle Micron Sizing

Figure 10. Hollow Cone Spiral Nozzle Micron Sizing

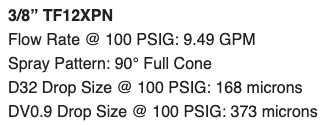

Bete nozzles provided micron data from their most popular used evaporation and snowmaking spiral nozzle tips. Bete’s engineer further stated the 3/8” TF12XPN is the smallest clog-resistant nozzle purchased for snow cannons or fan guns. See Figure 11 for the data provided by Bete. Bete provided additional data for smaller nozzles that are not as clog-resistant and have D32 droplet sizes at 112 and 140 microns. The models offered were the TF6NN and TF8NN.

Figure 11. Bete Fan Gun Nozzle Data

Figure 11. Bete Fan Gun Nozzle Data

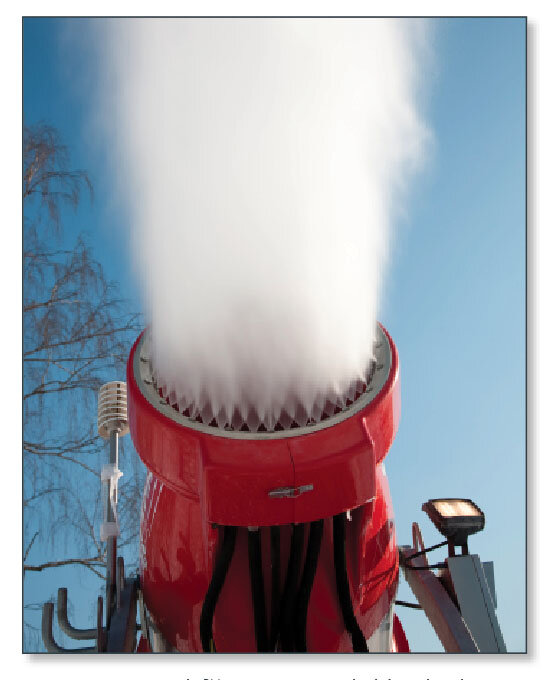

The snow cannon design used in many evaporation projects uses the concept of saturating ambient air flow with lots of water flow. The coalesced water begins its saturation point at the end of the cannon to cool the temperatures below wet-bulb when mixing with outside ambient air. Once the wet-bulb temperatures lower, snowmaking potential rises mostly in high altitudinal locations. Figure 12 shows the high amounts of saturation at the end of the fan-style evaporator. A two-year consumptive water loss from an artificial snow study determined a mean loss of only 6% from evaporation and sublimation during initial loss calculations. When you saturate the outside air to 100% humidity, the remaining water falls back to the surface, similar to rain.

The only in-depth evaporation study found using fan-style cannons and was performed in the Southeast United States near Savannah, GA. Due to the significant fallback associated with these styles of evaporation systems, much lower volumes of water were used with the spiral nozzles so that data could be collected. The Study concluded if significant fallback were tolerable, then the expectation of evaporation efficiency would be 10-12 GPM from the 70 GPM spray rate. This 17% evaporation rate during daylight operation only was never confirmed directly from the Study.

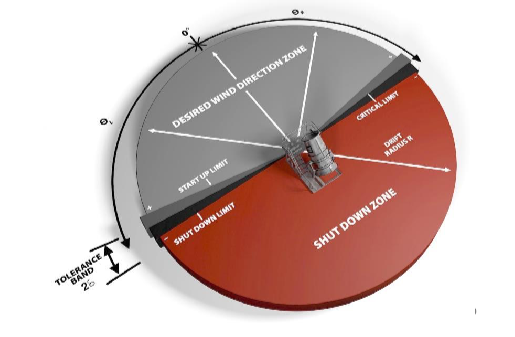

One of the other limiting variables for the fan-style cannon evaporators is when they operate from the land. Overspray concerns from differing wind directions throughout the day cause shutdowns that lower production. Figure 13 shows the 180 degrees of operational capacity.

Figure 12. Fan-Style Cannon Evaporator

Figure 12. Fan-Style Cannon Evaporator

Figure 13. Land-based pressure nozzle cannon shut down zone

Figure 13. Land-based pressure nozzle cannon shut down zone

Land-based cannon configurations have difficulty when winds blow back towards the saturated blast zone, which causes a severe overspray condition onto the land behind the system (Figure 14).

Figure 14. Overspray condition using land-based cannon

Figure 14. Overspray condition using land-based cannon

Figures 15 & 16 show the typical way cannons combat overspray so they can operate without shutting off as often. The cannons often get lowered to shooting the saturated stream directly back into the ponded water.

Figure 15. Cannon-style overspray position

Figure 15. Cannon-style overspray position

Figure 16. Cannon overspray setting in high wind region

Figure 16. Cannon overspray setting in high wind region

Other considerations during overspray operations are the mist digestion of dissolved solids back into the internals of the cannon fan blades and the fouling of the spiral nozzles, as noted in this Salton Sea study with a few notations bulleted below. Figures 17 & 18 show a cannon unit with mist digestion.

-

The nozzles on the units plugged up.

-

Mist fouling of the evaporators was a major problem.

-

The inline filters had to be cleaned numerous times per day to keep the units in operation. Left unattended, enough mist could be digested into the units to force the impeller blades out of balance.

-

The devices had to be shut down every couple of days and pressure washed both inside and outside of the housings. This process was time consuming and was an endless task in the course of project operations.

-

Mist fouling of the evaporators was a major problem. Any wind from a non- aligned direction resulted in mist surrounding the units. Much of the mist was sucked into the impellers of the turbo fans, resulting in deposits like those shown in figure 5.8. Left unattended, enough mist could be ingested into the units to force the impeller blades out of balance. The devices had to be shut down every couple of days and pressure washed, both inside and outside of the housings. This process was repetitive and time consuming over the course of project operations.

-

During the test the machine could average 54gpm throughput at a power consumption of 93 kwh. Our machine operates at 80gpm using less than 75kwh. The client must understand that this is gallons pumped through the unit not water evaporated.

To reduce, but not completely eliminate, the risk of mist digestion by the EES units, each EES unit would need to be robotically slaved to multiple wind direction, wind speed, and wind shear detection systems. Any fouling by mist digestion by a significant number of EES units would be very expensive and time consuming to clean up.

Figure 17. Mist digestion side view

Figure 17. Mist digestion side view

Figure 18. Mist digestion inside cannon

Figure 18. Mist digestion inside cannon

Another type of pressurized nozzle system (Figure 19) has recently entered the market. The design places a few pressurized atomization nozzles just above the top of the surface water. This nozzle placement helps the system alleviate some overspray concerns. The system doesn’t provide enough evaporative spacing above the water level, where studies have shown higher levels of saturated water vapor interfaces. Based on the Craig & Gordon model from 1965, turbulent dryer wind is needed to uplift the higher layers from their modeling interfaces.

Figure 19. Pressurized nozzle operating just above the water to vapor exchange interface

Figure 19. Pressurized nozzle operating just above the water to vapor exchange interface

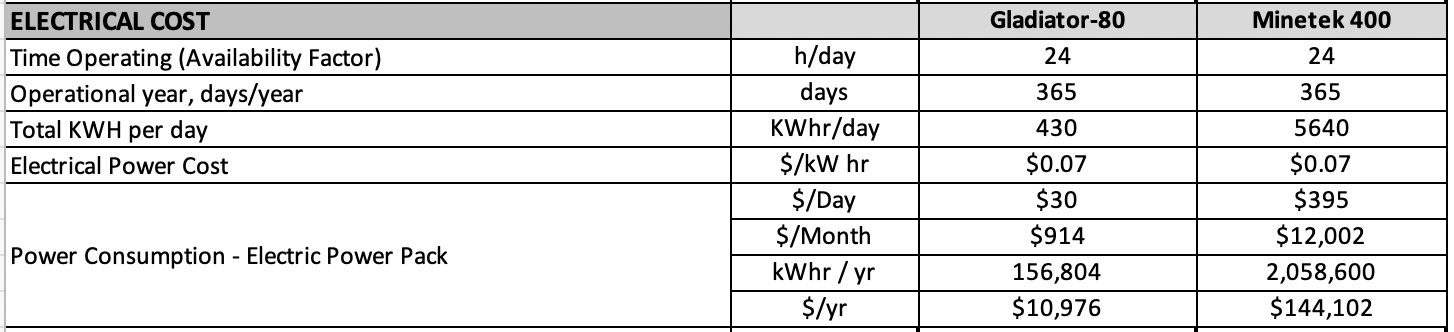

Efficiencies in electrical consumption/evaporation bear mentioning when comparing the differences between rotary atomization and pressurized nozzles for enhanced evaporation projects. Table 2 depicts the electrical differences between EK’s rotary atomizers and a typical Minetek cannon setup. The water cannon needs a separate 160kW water pump with a 75kW motor to spin the cannon blades, Versus EK’s Gladiator-80 unit only using 17.9kW.

Table 2. Electrical Cost Differences EK vs. Minetek

Table 2. Electrical Cost Differences EK vs. Minetek

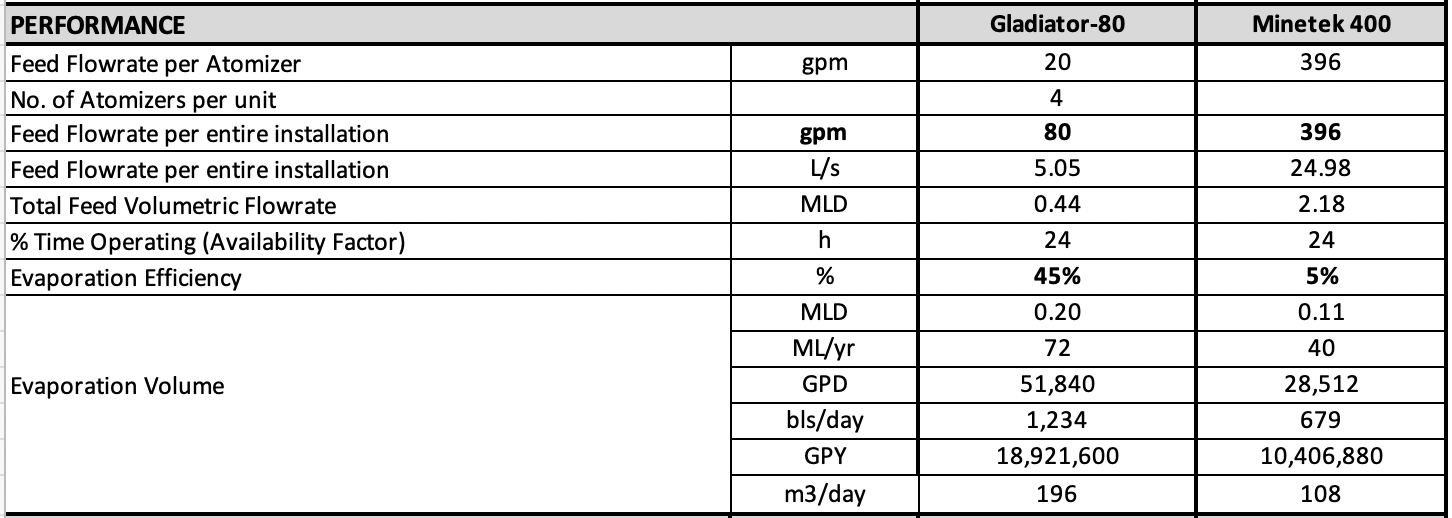

Performance comparisons in Table 3 show typical evaporation rates in high humid locations such as the Southeast United States. It would take two Minetek’s to equal the performance of a single Gladiator-80.

Table 3. Performance Differences between EK & Minetek

Table 3. Performance Differences between EK & Minetek

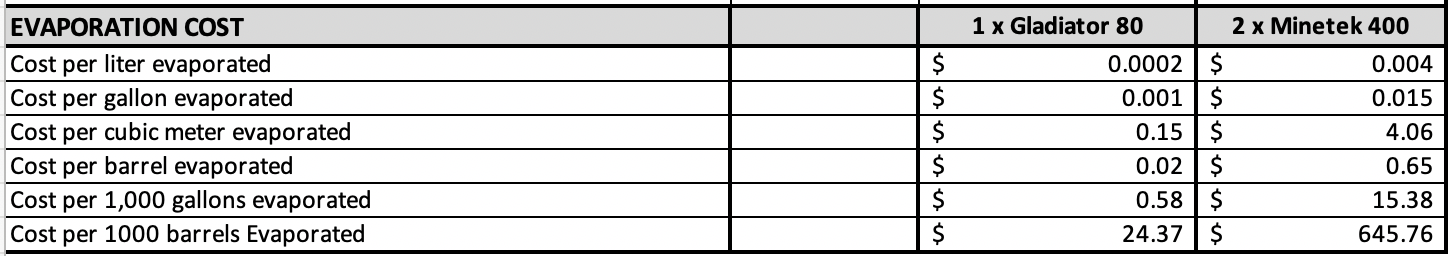

Table 4 depicts the evaporative volume OPEX cost efficiencies between the two systems and illustrates that higher water volume throughput doesn’t equal more evaporation. It does mean it will cost you more per gallon using multiple Minetek’s versus a single EK Gladiator-80 system to achieve a similar amount of evaporation volume.

Table 4. Actual Evaporation Cost

Table 4. Actual Evaporation Cost

There are many sustainable advantages related to using rotary atomization versus pressurized nozzles. The electrical cost alone shows the main differentiator in the side-by-side comparisons. The cannon-style evaporators aim lots of large water droplets high into the air, but many fall back. The EK rotary atomization method creates the industry's smallest droplets that quickly evaporate. Please feel free to reach out to one of EK’s accelerated evaporation experts to discuss how rotary atomization can effectively respond to your wastewater disposal needs.